|

|

From the Boatshop

by Ron Magen

Letters to Ron

Glassing the Hull -- A Question

Hello, All.

I have the Dobler's exterior seams taped and am about to turn the boat

over to tape the inside seams. Before doing that, however, I decided to

sand the outer seams and grind the tape edges down. It took me 8 hours! To

that point, I had been contemplating "glassing" the boat to the sheer

line. Who here knows the pros/cons of such an enterprise and would like to

give me their 2 cents worth? I would appreciate it.

Dennis

___________________________

Dennis,

I tend to agree with the other comments you've been given, I jut like to

add a few notes.

To 'cut down' chunks, runs, globs of filler . . . try a SURFORM TOOL. They

come in different sizes & shapes, with replaceable blades. Wait till the

stuff is relatively hard - not 'rock-hard' but still in the

green stage, just beyond the fingernail impression stage. Comes off like

you are grating cheese. Be careful around the actual glass cloth . . . can

rip through quickly and leave a very broken-up surface.

Another thing to try, if you intend to use paint later, is to try XYNOLE

or one of the polyester cloths. Supposedly non-itch, easier to stretch &

form, and apply from a 'roll'. The downside is that they absorb more

resin, and stay white instead of becoming 'water clear' in the matrix.

[I've gotten a sample and am going to do some testing. If it proves out I

will use it on my next major project]

Regards,

Ron Magen

Backyard Boatshop

Epoxy curing

We are in the midst of our first experience with epoxy and would like

some feedback. We are remounting our bow pulpit and are adding fillets to

the holes. We are using West Systems epoxy with the slow 206 hardener and

used the pumps for accurate dispensing. We used 1 pump resin and then

mixed silica with it until just thicker than catsup and then added a pump

of the hardener and mixed well, following Dr. Judy's instructions. We put

it into a Ziplock bag and piped it into the holes. It has been 85 degrees

here and now, 24 hours later, we are drilling the holes. I must add that

since the holes are for 3/8" bolts, the larger holes for the fillets were

drilled to 5/8". So there is quite a bit of epoxy in them. I think the

epoxy seems a bit flexible. I expected it to be rock hard. It has some

give and is easy to drill. Is this normal or is something amiss?

Karen Jxxxx

1998, P-19, Miss Maggie, #1010

___________________________

Karen,

Two points;

1) Epoxy typically takes better than 30 days to get to 90+ percent

'cured'. It is a geometric progression so that it seems 'solid' at 8 to 24

hours, depending on the ambient temperature.

2) As a general rule, the 'low ratio' mixes tend to be 'softer' or retain

more flexibility than the 'higher ratio' {5:1, 6:1} Resin-to-hardener

mixes.

My base is the RAKA 5:1 'mix'. It is a 'moderate speed' type at the 77

degree Standard Temperature. Epoxies are time/temperature dependent. Think

of it as a 'balanced equation'. While we can't control time {at least not

yet} we can control temperature.

Mixing the filler into the resin before adding the hardener was a smart

move. However, one of the major causes of problems with curing is

insufficient mixing of resin & hardener. That is why it is usually

recommended to add fillers last. The mixture is also exothermic. To give

yourself control of 'open time' use the chemist's trick of using a

temperature bath. Put your container in a pan of cold water, and use a

large container to increase the surface {heat radiating} area during warm

or hot weather; warm water and a smaller container when it's below 60

degrees.

Another advantage of the RAKA formulations is that you can combine

hardeners to 'fine tune' the mix. It takes a little forethought and

volume-marked containers because you are 'mixing' BOTH ratios {5:1, 2:1}

and amounts {x parts 5:1 hardener + y parts 2:1 hardener to z parts

resin}. Not as complicated as Celestial Nav, just a little thought. It

will allow the ultimate balance, and if you take good notes, easily

repeatable.

Regards and good luck,

Ron Magen

Backyard Boatshop

Epoxy ‘Life’ - Without UV Protection

A thought on UV protection (MAS epoxy).......is there anyway to

retain a bright finish with spar varnish over clear epoxy. I would hate to

cover up the grain of this $8 Lauan 1/4 inch ply. And does anyone have

personal account of epoxy longevity?

Mike in Mississippi (we have sun!)

___________________________

Mike,

You have answered your own question - Varnish.

SPAR varnish is a 'long oil' type and never 'really' gets hard. It's

original purpose is in it's name; to coat and protect wood spars, yet

allow visual inspection. It remains 'flexible' just as the spar is

flexible to take the strains & pressures of the rigging. DO NOT use on a

surface that will be sat upon or handled.

'Short oil' type varnishes do 'cure' to a hard state and can be handled or

have things placed on them without sticking. I used this type most

frequently, and apply a good coat of paste wax for further protection. In

the case of a rudder that I refurbished, the last coats of wax were a

Teflon 'boat wax' to improve the 'critter & slime shedding' yet allow the

Red Mahogany to show through.

These varnishes are available in the 'traditional' Amber hue, or the

'water clear' variety . . . just check the advertisements in almost any of

the nautical magazines.

Some years ago, just as an experiment and because I had some already

mixed, I brushed some 5:1 epoxy on a piece of 1/4 Lauan that I used to

replace a broken window in my back door. The window panel was on the

bottom half of the door, and I was using the wood because our Malamute

would 'knock' when he wanted in. I gave it a couple of not carefully

applied coats of varnish. It was exposed to all the weathering of a

Philadelphia suburban climate, plus the 'insistence' of a 120 pound

Alaskan Malamute. It started to look a 'little worn' after 3 years, and

some wood showed through after about 5. I turned it around to the 'epoxy

only' side and got another 2+ years out of it.

Just think what you can do with some simple maintenance; quickly

'touch-up' any chips or nicks, and give it an occasional 'freshening' coat

annually or when YOUR environment requires it.

Regards,

Ron Magen

Backyard Boatshop

Gold Paint - Revisited

"Steve" wrote:

A few months ago someone wrote about people looking for a source for

gold paint. In years past, I had searched and searched for gold paint

without much luck. It seemed there was nothing available for exterior use

and the gold paint sold to sign painters didn't stand up very long in the

marine environment.

I just came across a product that is sold by AWLGRIP. It's Gold

Metallic Powders that you mix with their Low Solid Clear Urethane topcoat

(G3003). They offer a Pale Gold (5083) AWL # 73010 or Cordovan Gold (5093)

AWL #73011.

I've never seen it in any of the marine stores, but it is listed in

Fisheries Supply Catalog, here in Seattle. I would expect that it could be

special order from other dealers of AWLGRIP paints.

Steve

S/V Good Intentions

___________________________

Steve,

From what I understand ANY AWLGRIP product is EXPEN$IVE !!. If it indeed

has GOLD in it, then the user had better be privately endowed.

The usual reason for 'tarnishing' is oxidation; therefore if the surface

is 'protected' from the oxygen in the air, it should retain it's original

'tone' for some time.

Even Gold Leaf comes in different 'carets' and tones . . . as well as

'imitation Gold Leaf'. Personally, my idea of the gold 'color' for boat

work is more of a 'Burnished Bronze' look.

I have a few small bottles of 'metallic gold paint' with some complex

application schemes. {When SOMEONE wants to PAY for my 'learning curve',

then I'll use real leaf}.

Most recently I got a QUART of 'oops paint' at Home Depot. It was

'Ballroom Gold' {by a 'well-known designer'} and only 50 cents . . . so I

added it to my 'collection'. Although it is specified for indoor use, I

have made several items which have been outside for SEVERAL MONTHS. One

use is on a series of 'Boat Planters' I made for my wife & others, and the

other is in my carved shop 'sign'.

The basic concept was to apply it in a similar fashion to the method used

for gold leaf. For the 'Boat' it was the 'Bow Eye'. Although the original

plan called for white trim, I varnished the Mahogany foredeck, and wanted

the eye to complement it. First I dry fitting the piece and pre-drilled

the screw holes. I sanded the piece of Red Cedar, then sealed / 'sized' it

with a thinned coat of varnish. After the varnish cured, I lightly sanded

it and applied two coats of the water-based Ballroom Gold Acrylic. Again,

sanding carefully between coats. After it dried, I applied several coats

of Spar Varnish in the usual manner.

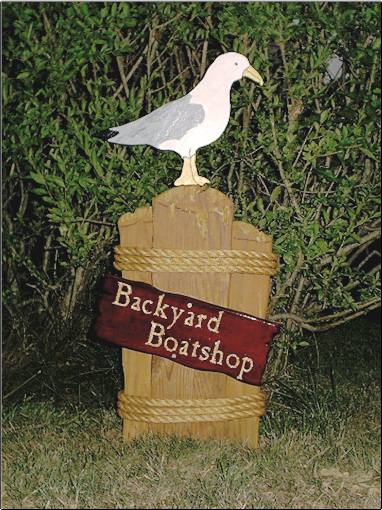

The sign was almost the same, but with a twist. Because the letters were

'engraved' and not a separate piece I had to think about removing excess

material. BEFORE I did the hand-engraving, I stained the blank and gave it

a couple of coats of short-oil varnish to seal & smooth it. I then placed

my templates and carved away. After cleaning up the letters, I gave them a

coat of varnish, wiping off the excess, from the 'cured' surface, with a

swipe of mineral spirit moistened paper toweling. Then followed about four

coats of the gold paint, heavily dabbed & dribbled into the letters, again

with the excess easily wiped away. This was then followed by about four

coats of Spar.

To see how that turned out, look at this illustration from my

column about people stealing things.

Regards,

Ron Magen

Backyard Boatshop |