|

Obsolete Outboards |

|

| by

Max Wawrzyniak - St Louis, Missouri - USA

Bringing

a 1956 Johnson 15 hp Back to Life

Part

III: Removing

the Flywheel and Magneto |

|

Part

1 - Part

2 - Part 4 - Part

5 - Part 6 - Part

7

Before we get started on the magneto, you

might want to review the magnetos

column.

Some people like to check for "spark" before

they start mess'n with the magneto. Checking for spark

means removing the sparkplugs from the cylinder head,

gounding the outer metal casing of the sparkplug to

a good "ground" (bare metal) somewhere on

the engine, and with the spark plug wires still attached

to the plugs, cranking the engine with the recoil

starter or with a piece of rope wrapped around the

flywheel. If everything is working correctly you should

be able to see the plugs sparking and also hear an

audible snapping sound. A white spark or blue spark

is preferable to a yellow spark.

|

SF17 -

"Inspection" hole in flywheel

through which you can check for cracked

coils. You can also adjust the ignition

points "gap" (we will get to

that) through this hole.

(click

images to enlarge) |

|

I don't bother with checking for spark before tearing

into the magneto. If I intend to run the engine myself

(and I rarely work on other's engines) then I want

it to have a tune-up. The cost of putting new ignition

points and condensers, new spark plugs, and maybe

new spark plug wires into one of these old OMC outboards

is usually no more than about $25.00 assuming you

buy the parts and install them yourself. When you

pay a shop to work on your outboard you will usually

end up paying full retail price for the parts, but

with a bit of shopping you can often buy the parts

(to be isntalled by yourself) at a discount, which

means you not only save the labor charges but also

save a little on the cost of the parts themselves.

Replacing these items, which are more-or-less considered

"expendables" or "consumables"

will save you some frustration when it comes to getting

the engine into running condition and will also give

you a better-running engine.

As mentioned in the Magnetos

column, the one area of weakness in all

1 and 2 cylinder OMC engines manufactured from about

1951 until the late 1960's are the magneto coils.

These coils, which resemble round plastic cylinders,

always go bad, without exception. If your engine has

the original coils, it is a sure sign that the engine

has seen very little running (if any) in recent decades,

and the coils will have to be replaced. Many OMC outboards

you will run across, however, will have already had

the coils replaced and as the replacements rarely

go bad you can run them.

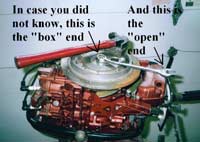

| SF18 - A box-end

wrench provides a much better grip on the

flywheel nut than an open-end wrench does.

Less chance of "stripping" the

"flats" off the nut, especially

if you hit the wrench with the hammer as

I do (not recommended by the factory) |

|

|

With the recoil (pull rope) starter removed, look

to see if there is an inspection port (hole) in the

top of the flywheel; most all of the old OMC outboards

of under 25 hp had this hole. Usually it had a sheet

metal cover although often the hole cover is missing.

Have a look down into this hole as you slowly rotate

the flywheel by hand (OSHA would have you remove the

spark plug wires to be sure the engine does not start

while you are turning the flywheel. Yea, right. Removing

the spark plugs as well makes the engine easier to

turn - no compression). You will see the two cylindrical

plastic coils which may be green or red or purple

or maybe some other color. If there are cracks evident

in the plastic, you have bad coils even though you

just might still get a spark out of them. No cracks,

and the coils are PROBABLY good. Replacement coils

can be had at Johnson and Evinrude dealers or aftermarket

Sierra coils (part # 18-5181) can be purchased through

any boat dealership or through NAPA auto parts. The

Sierra coils list for about $21 each and sometimes

the boat dealers will discount them a little. By the

way, only turn that flywheel clockwise, looking down

on it. Otherwise you risk damaging the water pump

impeller you just installed.

In order to go any further, one (you) must remove

the flywheel. The proper way to lossen the flywheel

nut is to hold the flywheel stationary with a big

strap wrench while loosening the nut with another

wrench. I don't have a strap wrench big enough to

go around the flywheel so I put a box-end wrench (better

than an open end wrench, and a six-point box is better

than a 12 point box; if you don't know what I am talking

about, do a Google search) and give it a persuasive

tap with a hammer while holding the flywheel still

with the other hand which also holds the wrench from

sailing.

SF19

- The puller in place on the flywheel: note

that the puller mandrell (center big screw)

is in line with the engine's crankshaft,

that the (3) smaller bolts are threaded

fully (but not excessively) into the (3)

holes in the flywheel; that the flywheel

nut has been "backed-off" a few

turns but is still on the crankshaft and

lending support to the crankshaft (but the

nut is NOT taking the thrust from the puller

directly). The orange handled handled screwdriver

is to keep the flywheel from turning as

the mandrell is tightened. SF19

- The puller in place on the flywheel: note

that the puller mandrell (center big screw)

is in line with the engine's crankshaft,

that the (3) smaller bolts are threaded

fully (but not excessively) into the (3)

holes in the flywheel; that the flywheel

nut has been "backed-off" a few

turns but is still on the crankshaft and

lending support to the crankshaft (but the

nut is NOT taking the thrust from the puller

directly). The orange handled handled screwdriver

is to keep the flywheel from turning as

the mandrell is tightened. |

|

Loosen the nut a few turns but don't remove it: leave

it threaded onto the crankshaft (which is what the

flywheel is bolted to) and set-up your flywheel puller.

If you don't have a flywheel puller you are going

to need to borrow one or buy one. While I don't intend

to endorse any one tool source over another, something

like this will work just fine.

You might need to stop off at the hardware store

if the bolts for the "legs" that come with

the puller are the wrong diameter to thread into the

three holes in the top of the flywheel. You do NOT

want to use a puller that lifts up on the other rim

of the flywheel as that may damage the flywheel. the

puller MUST pull from the three threaded holes on

the top of the flywheel.

SF20

- The flywheel has been removed, revealing

the magneto. The coils do not appear to

be cracked and we will assume that they

are "good." If you are only replacing

the ignition points and condensers there

is not need to remove the magneto from the

engine. I would strongly suggest, hwoever,

replacing the spark plug wires with new

metallic core (not graphite) wires if the

old ones appear to be stiff and brittle

or are cracked, in which case you will need

to remove the magneto from the engine. Note

the little sheet metal clip that can be

used to disconnect the htrottle linkage

that rotates the magneto for "spark"

advance. SF20

- The flywheel has been removed, revealing

the magneto. The coils do not appear to

be cracked and we will assume that they

are "good." If you are only replacing

the ignition points and condensers there

is not need to remove the magneto from the

engine. I would strongly suggest, hwoever,

replacing the spark plug wires with new

metallic core (not graphite) wires if the

old ones appear to be stiff and brittle

or are cracked, in which case you will need

to remove the magneto from the engine. Note

the little sheet metal clip that can be

used to disconnect the htrottle linkage

that rotates the magneto for "spark"

advance. |

|

Thread the three bolts down through the puller and

into the three holes of the flywheel as shown in above.

The bolts must be fully-threaded into the holes, but

if the bolts are threaded so far into the flywheel

that they protrude underneath, and if the flywheel

is then rotated, the bolts can damage the ignition

components under the flywheel. Once the puller is

installed, do not allow the flywheel to turn. The

puller is tensioned by turning the large threaded

center mandrell (bolt), the bottom of which has a

pointed do-dad on it which will self-center in the

center depression machined into the end of the crankshaft.

The flywheel nut should remain on the crankshaft threads

to help support the crankshaft but the puller should

bear against the crankshaft and not the nut. Be sure

that the nut is loosened a few turns, however.

I use a large screwdriver inserted into the legs

of the puller to keep the flywheel from turning as

I tighten the mandrell, but the proper tool to use

is that big strap wrench which I don't have.

SF21 - The (4) screws marked #17 are the

screws that secure the magneto to the engine.

The item marked #15 is the clip for disconnecting

the throttle linkage so that the magneto

can be removed. Although this linkage may

be different on some larger engines, the

arangement of the rest of the magneto components

is common to all 2-cylinder OMC outboards

manufactured from about 1951 until the early

1970's.

SF21 - The (4) screws marked #17 are the

screws that secure the magneto to the engine.

The item marked #15 is the clip for disconnecting

the throttle linkage so that the magneto

can be removed. Although this linkage may

be different on some larger engines, the

arangement of the rest of the magneto components

is common to all 2-cylinder OMC outboards

manufactured from about 1951 until the early

1970's. |

|

Make sure that the mandrell of the puller is in-line

with the crankshaft and not leaning one way or the

other.

The flywheel is seated on a taper machined into the

end of the crankshaft and if the flywheel has not

been off in a long time, it may take considerable

tension to break the flywheel loose from the crankshaft.

How much tension is difficult to quantitfy. In other

words, I don't know. What I do is to screw-down the

mandrell of the puller as much as I dare. If the flywheel

has not come loose yet, I will lift up on the flywheel

and give the top of the mandrell a persuasive tap

with a hammer. If you grab the flywheel and lift up

on it, you will notice a tiny bit of "end play":

the flywheel and crankshaft will move up and down

a very tiny amount, maybe a couple of thousanths of

an inch. Have someone lift on the flywheel so that

the flywheel is at the upper end of it's end play,

and hit the top of the puller mandrell with a hammer-blow

straight down. Often this will break the flywheel

loose. Do NOT hit the puller with the hammer unless

the flywheel is being lifted, and make sure the hit

is square and straight. I don't know how to tell you

how hard of a hammer blow I give the puller, but it

is certainly not a "timid tap" nor is it

"everything I've got." If a couple of hammer

blows don't free the flywheel, put the hammer aside

and give the mandrell maybe another 1/2 turn or so

and then try the hammer again.

| SF22 - This

is the entire ignition system for (1) cylinder,

along with some of the potential problems.

The components are few and cheap: Why waste

your time cleaning and "dressing"

pitted points and checking for shorted condensers

when new ones for the engine will cost under

20 bucks? |

|

|

If a few hammer blows have not freed the flywheel

and you dare not put any more tension on the puller,

soak the crankshaft with penetrating oil (WD-40 is

not prenetrating oil) and let it sit over night.

If it still will not come loose, use a propane touch

(like is used for soldering copper pipes) and rapidly

heat the flywheel around the crankshaft while trying

to avoid heating the crankshaft too much, all the

time keeping the puller under tension. After heating

the flywheel for several minutes, put the tourch down

and try the hammer again.

Some combination of all of the above should free

the flywheel. If the flywheel hase been recently removed,

it may come loose easily with no need for hammers

or tourches or oil, but if it has been stuck on that

crankshaft for 40 or 50 years. you may need to use

all of the above in order to get it loose. By the

way, a really stuck flywheel will make one heck of

a "bang" when it pops loose.

|

SF23 -

Removing the magneto: loosening the (4)

screws marked # 17 in Figure SF 21. Note

that the throttle linkage has been disconnected. |

|

Once the flywheel is removed you are looking at your

magneto (Figure SF 20). Each of the two cylinders

has it's own coil, ignition ("breaker")

points, condenser, spark plug wire and spark plug.

Other than some magnets embeded in the rim of the

flywheel, and a cam (eccentric) on the crankshaft

that acts upon the points, that is all there is to

the magneto and the whole ignition system (figure

SF 22). I highly recommend that you replace the ignition

points and the condensers at a minimum and these items

can be changed-out with the magneto remaining on the

engine.

If the spark plug wires look old and have turned

hard and/or have cracked, it would not be a bad idea

to replace those as well, and for that the magneto

needs to be removed from the engine (which is not

a big deal). The magneto also needs to come off if

you have cracked coils which need replaced.

| SF24 - Magneto

removed. Unless the flywheel is really really

stuck on the crankshaft taper, you should

be able to go from a fully-assmebled engine

to this state of dissasembly in about 30

minutes or less. |

|

|

The magneto can be rotated back and forth and this

is how the igntion timing is advanced and retarded

as the engine is speeded-up and slowed down. The rotation

of the magneto is controled by an arm and bellcrank

arangement on the port side of the motor and there

is usally a sheet metal clip which can be removed

without tools in order to disconnect this linkage

(figure SF 20). Four screws (#17, Figure SF 21) are

loosened and then the magneto can be lifted up off

of the engine. Be carefull that the arms for the ignition

points do not "hang-up" on anything while

you are lifting the magneto off the engine. The only

wires hanging off the magneto will be the (2) spark

plugs wires, unless you have a "push to stop"

button in which case you will also have two small

wires. The small wires usually have disconnects which

are often hidden beneath little plastic sleeves on

the wires.

Since I keep reminding myself not to make any assumptions

about how much the reader knows, this is getting a

bit "wordy." and so the magneto work will

drag on into next month's column as well.

Bye Bye

click here for a

list of Columns by Max Wawrzyniak

|