| To

Part One

Part Two - Chargers and Main Power

Last time we looked at replacing and repairing battery packs

in rechargeable tools. I didn’t have the battery back from

the Batteries+Bulbs store at press time, but here’s a photo

of their handiwork.

|

Battery rebuild |

Nice! But we still have a charger issue or two. First, I have

no charger for the Black & Decker style battery. Second, the

Ryobi battery was palpably warm after charging – it would

seem the charger isn’t controlling the charge rate as it

should. This might be because the cells were so worn out, or it

might be why the cells were so worn out.

Again I refer to James Wilf’s article at:

https://homepage.ntlworld.com/wilf.james/nicads.htm

He provides a design for a “dirty DC” charger. Here

is how I put it together for charging a 14.4 volt battery.

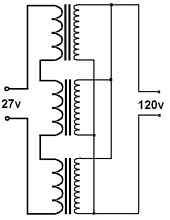

Cheap transformers

The transformer voltage needs to be 1.5-2 x the battery voltage.

In this case that means 22-30 volts. I’ll bet you don’t

have a transformer in that range laying around, do you? There

are a couple choices. One way is to gang together some unused

9v wall wart transformers like so:

|

Gang transformers |

Most of these don’t handle much current, but this might

be OK for normal charge rate. The normal charge rate is 1/10 the

amp hour rating of the cells. Mine are 1200maH cells, so I need

to charge at 120 mA. A lot of wall warts will fall short but you

might find a few that can do the job. (At the fast charging rate

of 1200 mA, forget about it!)

The other problem is mounting them. Generally the diode is inside,

and you need to get rid of it to make the circuit above. After

cracking open the cases it takes a bit of engineering to invent

a way to fasten those little transformers to a baseplate –

they usually don’t have any screw holes!

I think it is a lot simpler to rewind one big transformer. Fortunately

you can get the raw materials dirt cheap. Microwave ovens are

a form of trash that most people have to pay to get taken away.

This makes it easy to get some free ones that are dead or simply

unwanted. Usually the transformer is still good in a dead oven.

(Be sure to also harvest the big magnet from the magnetron –

very handy for holding screwdrivers and chisels! Even hammers

– they’re quite powerful.)

| MOTs |

|

Microwave ovens transformers (MOTs to transformer hackers) are

designed to provide a constant current supply at very high voltage.

We don’t care so much about that, but it does make them

super easy to rewind – the primary and secondary windings

are completely separate! On normal transformers they are wound

in layers. An excellent article on rewinding can be found at:

https://www.users.on.net/~endsodds/psrewind.htm

So I’ll just cover what I did.

I had already removed the secondary windings (the one with the

finer wire) from some of these transformers, so the first step

is to figure out how many volts per turn it will generate. This

is easy. Wrap a single layer of scrap lampcord around the core

and measure the output voltage. (Actually, first wire a fuse into

the primary! Start with a small one, too. I don’t want to

belabor the point, but electricity can kill you, so be smart.)

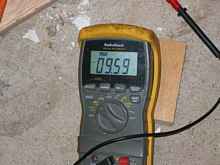

|

MOTs test |

With 9.59 volts and 8 turns, this one came out to 1.2 volts

per turn. So if I want 29 volts, I need 24 turns. These turns

can be made with any wire with insulation that can stand 50 volts

or so, and that has a big enough cross section to conduct 200

mA. But bigger is better, if you can fit it. I used 22 ga magnet

wire, mostly because I had some. Its maximum current rating is

1.28 amps, which is just barely beyond our maximum fast charge

rate of 1.2 amps. This is fine for me, since I only plan to charge

at the normal rate. You can see why given my history of cooking

batteries.

While you’re testing volts per turn, also measure length

of wire per turn. Most MOTs have the laminations welded together,

so you won’t be able to take the transformer apart and wind

the coil the easy way. Fortunately, with so few turns we can pre-measure

the wire needed (plus some extra!) and “sew” it through

the core. Be sure to wrap the core in electrical tape first to

protect the wire’s insulation from sharp edges, and be careful

not to kink the wire while feeding it through. It took me maybe

an hour to wind this one.

I guess I’d better explain how transformers work for those

who aren’t familiar with them.

How transformers work

If you go looking for articles online about how transformers

work you will find two main categories. The first is written by

engineers, for engineers. They go into detailed measurements and

complex math that we have no need to care about. The other category

or articles is by audiophiles/guitarists, who can go on for ages

about the sound quality of various output transformers. Again,

our needs are far, far more basic.

A transformer is like a gearbox. Imagine voltage as shaft rpm

and current as torque. To transfer a lot of torque a low rpm,

you need a huge, strong shaft. This is analogous to a fat wire

for high current and low voltage, like arc welding. Arc welding

is like driving in 4x4 low range, broken shafts and melted wires

(or welding rods) being analogous. To transfer the same amount

of power at high rpm, the torque will be lower and the shaft will

be smaller. Think of the tiny output shaft of a weed whacker powerhead

– very little torque needs to be transmitted because it

runs at like 7,000 rpms. This is also why we transmit power long

distance on “high tension” (high voltage) lines –

we need less metal to move the same amount of power. It is like

using higher rpm to reduce the torque.

When we need to change rpms, we use a gearbox or pulleys. The

small, fast shaft coming out of your motor gets geared down lower

to put the same power into a slower, fatter shaft that goes to

the wheels. This is exactly what a transformer does. The high

voltage from your wall socket can be stepped down (or up) to whatever

voltage you need.

But how?

The number of turns in the transformer’s primary winding

is analogous to the diameter of the driving pulley, and the number

of turns in the secondary is analogous to the diameter of the

driven pulley. Instead of gears meshing to transfer power, we

have a magnetic field vibrating back and forth.

By the way, that “back and forth” part is important

– this only works with alternating current. The magnetic

field can only induce a voltage in the secondary when the voltage

in the primary changes. Put direct current in and you create an

electromagnet, but no current is induced in the secondary.

Now when you’re done with this article, you should re-read

Max Wawrzyniak’s bit on how outboard ignitions work. It

will make a whole lot more sense now, since the magneto uses the

same electromagnetic principles, only with a moving permanent

magnet.

OK, back to Mr. Wilf’s charger.

Charger Details

We now have the transformer. I wound mine to 28.8 volts (24 turns)

with the idea of using an automotive 1157 bulb as the series resistor.

The “major” filament (the bright one) is around 6

ohms, and the minor filament is a bit under 24 ohms. For slow

charge I use two 1157s with all filaments in series to get about

60 ohms. Any one of these filaments could easily dissipate the

7.2 watts of heat we’re dealing with here, and in series

they all share it. We’ll be lucky if they even light up.

So how do we find out? First let’s “breadboard”

the circuit. If you ever hear electronics types talking about

“breadboarding” a circuit, this is where the term

came from. Back when men were men and components were enormous,

you could cobble your circuit together literally on a breadboard

before bothering to build an enclosure for it. Nowadays breadboards

are little things with sockets for integrated circuits and other

tiny components. Well, unless you’re me. Here’s the

circuit breadboarded.

| First charger |

|

Those terminals are the same copper nails that are handy for

clench nailing the butt straps on instant boats. (This is all

I use them for now, since I’m pretty sure the Payson fiberglass

butt joint is a better way to go in every way.)

Notice the bulbs weren’t lit. This is true even when it’s

plugged in because there is nothing to draw current. I didn’t

want to hook it to the battery without some kind of test, however.

So let’s short the leads! This might sound reckless, but

it is a reasonable test, actually, since the bulbs are meant to

limit current and the battery cannot possibly draw more current

than this.

|

One filament |

Well, we can immediately see a problem. As I predicted above,

only one filament in each bulb is lighting up. That's a problem,

too, since the resistance changes as the filaments heat up, and

we're counting on the higher resistance of a red-hot filament.

Let’s get an idea how much current we’re actually

running here. To do this we measure the voltage drop across a

known resistance. The resistance of the bulbs is not exactly “known”,

since it changes so much with temperature. To get a better measurement,

I hooked an 8 ohm power resistor between the charging leads.

|

Resistance test |

The voltage dropped across this resistor was 5.056 volts. Ohm’s

Law says that volts / resistance = current, so 5.056 volts / 8

ohms = .632 amps. 632mA is far beyond the normal charge rate of

120mA.

OK, let's try a different bulb. A 194 is designed for .27 amps

at 14 volts, which should equate to 51.85 ohms. We're shooting

for 60 ohms, so this might put us in range. One problem is that

our voltage is higher than the bulb can tolerate, so we'd burn

them out pretty fast. If we put two in series, they can tolerate

twice the voltage, which should fix this problem. But this also

doubles the resistance to around 104 ohms, and we'll charge slower.

But we can put two of these pairs in parallel to cut the resistance

in half...back to the original 51.85 ohms!

| 194s |

|

Another thing I like about the 194 is that one can easily unbend

the terminal wires and fasten them. They do not solder well at

all, but screw terminals would work fine. (I would literally just

use some screws.) They are also cheap at around $1.50 each, and

no need to buy a socket. Here's what it looks like with some bad

solder joints on copper nails.

|

194 quartet |

The quartet of 194s tested at about 190mA, which is a bit quicker

than the rate I wanted for this battery, though probably still

reasonable. For a 1800mAh battery it would be perfect. For a 1200mAh

battery I'd rather back it down a bit, so I don't have to watch

it as closely (You already read how well I do in that situation.)

We can do this in one of two ways. Either we can run only one

pair of 194s to cut the current in half, or we can peel a few

turns off the transformer. Removing two bulbs is easiest, so let's

try that first.

I also removed the shunt resistor because this dirty DC makes

my meter's display jump all over. It seems to do it a tiny bit

less without the shunt for some reason. The proper tool would

be a vacuum tube voltmeter with its nice, smooth analog action,

but mine is currently out of commission, I'm afraid. It’s

on a long list of winter projects.

Anyway, with two 194 lamps, I again clipped in the 8 ohm resistor

and measured a 1.08 volt drop across it. I also measured an 11.31

volt drop across the pair of lamps. This tells us something extremely

useful. Here it is graphically first...

| Lamp resistance |

|

Again our friend Dr. Ohm tells us that because we have 1.08

volts dropped across 8 ohms, 0.135 amps must be flowing. (That’s

point B to point C above.) The same amount of current must be

flowing through the pair of 194 lamps, since they are in series

in the same circuit. Since they are dropping 11.31 volts (point

A to point B above) and we know 0.135 amps are flowing, we can

deduce that their combined resistance when heated is 83.78 ohms.

This is very handy, since we can't measure that resistance directly

very easily while power is running through them.

135mA is pretty reasonable for this battery, but here's the truly

cool part: now that we know the effective resistance of the lamps,

we can measure the current flowing into the battery whenever we

like! For example, with the battery almost fully charged, the

lights get dim. Only 3.75 volts is being dropped across the lamps.

If they are still 83.78 ohms, the charging current is 4.47 mA.

(Though when they get very dim, I suspect the resistance starts

to drop. An experiment with a different larger value fixed resistor

could confirm this.)

To finish the charger I added back the 1800 ohm shunt resistor.

Also note that I have to point a fan at the charger when it's

running. Even though we are underusing the potential power of

the MOT, it still heats up without a cooling fan. The diode is

a 1N5404, which can handle a full 3 amps. Mr. Wilf recommends

over-rating the diode by a factor of 5-10, so a 3-amp diode is

a bit of overkill, but for 7 cents why not?

Polarity

I’m sure you noticed my barely-labeled leads. It is of

course critical that you hook them up the right way, but there

is actually no need for a label. With no power connected, hook

the leads up. If the bulbs light up from the battery’s power,

the leads are backwards. Reverse them and charge. I intentionally

do this every time to make sure I have them on correctly before

plugging the charger in.

Smart charger tricks

While taking apart these batteries I noticed a few things. The

Ryobi batteries have temperature sensors taped to one of the cells.

When the sensor starts to heat up, the charger shuts down to prevent

boiling away the electrolyte. Clever. Except it doesn’t

do as much good if the cell with the sensor happens to be one

of the stronger cells. A weaker cell could be overheating and

the charger would never know. Still, one sensor is better than

none. Since the Ryobi cells are all weak and I have the official

charger, I guess I’ll rely on that for now. But I did keep

the sensor from the dead pack. This might play into future plans

for smarter charging.

The Black & Decker has no temperature sensor at all. This

was a bit surprising, since I generally think of Ryobi as the

very bottom of the market, unless we count the thoroughly useless

Chinese-made store brands like Tool Shop. However Black &

Decker does have a sort of a sensor – they add an extra

wire from between cells 6 and 7. This allows the charger to test

each half the battery separately. I assume that it compares them,

and if the difference is too great it decides that a cell is dead

and refuses to charge. It’s pretty simple to apply this

without the “official” charger. Every few charges

I test both sides of the B&D battery, just to see if a cell

is on its way out.

Save the orphans – mains power for cordless tools

So how about that Ryobi drill with the dying battery? For that

matter, I also had a Skil that was missing any kind of battery.

OK, so we have a couple good drills with no power supply, and

a half-dead power supply (the battery charger) of about the right

voltage.

Paging Dr. Frankenstein…

Actually, we’d better first page Dr. Ohm and figure out

if this is likely to work.

Theoretically this car charger can produce 6 amps at 12 volts.

This seems like a reasonable draw for a drill motor, so let’s

try it. I hooked up the power to the drill with jumpers. Sure

enough, it runs! But the ammeter buries on start-up and whenever

the motor slows almost to a stop under load. And I mean it buries!

I could hear the needle click against its stop at the extreme

top of its travel. Next stop after a huge current draw is normally

a melted transformer, so started thinking of ways to limit current.

Current Limiting Strategies

The three main ways of limiting current are a fuse, a resistor

or a non-linear device.

A fuse is simple – it is just an intentionally thin spot

in the wire that heats up and burns out before everything else.

It also doesn't waste any power before it blows, which makes it

a winner for common circuit protection. However, when these drill

motors hang up, they draw a lot of current. Almost like a dead

short. This means blowing a fuse for almost every screw you put

in. That's no good here.

The resistor is simple too, but we are limited by the linear

reaction of the resistor. We would prefer something that increases

in resistance as more current flows. Well, as it turns out we

already looked at a non-linear device.

A lightbulb goes on

Yup, back to bulbs. For the same reason it is a pain to measure

the resistance of a bulb, it is great for limiting current. Its

resistance increases with temperature. More current = more heat

= more resistance = less current.

Just make sure it is in series with the load, not parallel as

it would commonly be wired. Wire it like a fuse – if you

unscrew the bulb, the power should turn off.

This seems like a very low-tech solution, but actually it’s

not. This strategy was used in the Wien bridge oscillators that

first put Mr. Hewlett and Mr. Packard on the map. You can find

bulbs protecting treble drivers in some rather nice sound reinforcement

equipment as well.

The trick is getting the right size.

Right-sizing

Fortunately the engineering involved is very basic. Above we

mentioned that the charger can produce 6 amps at 12 volts. Multiply

the two numbers together to get 72 watts. A 72 watt lightbulb

should limit the current to about what the transformer can handle.

Let’s play it a little safer, however, and go with a 100

watt bulb.

In this setup, a 100-watt bulb lights up dimly when the drill

is not in use.

|

Drill rigs |

When I pull the trigger it light brightly, then drops down to

a moderate level. This is because the motor is only drawing a

moderate amount of current. If I grab the chuck and stop the drill,

the motor draws its maximum, and the bulb lights brightly. But

the needle on the ammeter never buries itself. Perfect!

Almost.

Or maybe not...

This concept of the current limiting transformer got me thinking

– why didn't the mains fuse blow when I stopped the drill

and the ammeter needle buried? Clearly it wasn’t drawing

all that much current on the primary side of the transformer.

Furthermore, I could hold it that way for some time without smelling

windings burning, even without the lightbulb in series!

Let's have a closer look. All we need is a cast off lamp cord

with banana plugs soldered to the ends, so we can plug it into

a multi-tester.

First the secondary (the drill side). When I'm not pulling the

trigger at all the voltage is 14.21 volts. (Well look at that—I

guess it somehow fixed itself! I believe the patient is having

second thoughts.) Turning the drill on with no load drops the

voltage to 9.85, and the bulb lights up moderately. A lot of that

voltage is probably getting dropped across the bulb. Forcibly

stopping the drill drops the voltage to 1.28 volts. It is also

easier than it should be to stop the drill. Let's take away the

springboard effect of the bulb.

Now choking the drill drops our DC voltage to 4.53, and the drill

still generates enough torque to chap my hands. So now let's check

the mains voltage side of the equation. My voltage at the end

of the extension cord is 117.3, which is not particularly great.

But forcibly stopping the drill only takes it down to 114.8.

To truly figure out what’s going on, I’d need to

add a fixed resistor to the mains side and measure current. But

even intuitively we can guess that the transformer is the limiting

factor here – there’s a lot more voltage drop under

load on the secondary than the primary. To me this means that

the transformer is saturating – it’s magnetism is

working as hard as it possibly can – before the full magnitude

of the short can be applied to the primary.

Why bother?

Part of the reason I bothered with this is the hand-operated

chucks on cordless drills. These are much quicker and more convenient

for bit changes. Another is the clutch, which makes it a lot quicker

and easier to drive screws just the right amount. Another reason

is this approach made use of several orphaned tools. It is nice

to be able to set them up with separate bits for a project and

plug them into the same power supply.

Of course this setup has some limitations. I’m depending

on a transformer that apparently suffers from mood swings, for

one.

Of course I could always wind something with one of my spare

MOTs.

Rob Rohde-Szudy

Mazomanie, Wisconsin, USA

robrohdeszudy@yahoo.com

*****

|