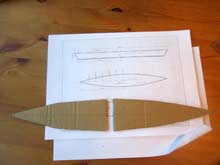

| Looking for a simple canoe to build out of plywood. I stumbled upon the “Cheap Canoe” from www.bateau.com. To get a feeling of the building process and also it’s 3D dimensions characteristics, I decided to built a model on scale (1:10) in carton-board.

|

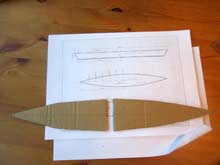

Using the offsets and drawing instructions as indicated in the free plans. |

|

Two bottom halves next to the plans. |

|

Bottom with butt blocks into one piece, same for the side panels. |

|

Using a hot-glue (hobby) gun to make a boat out of it (this is kitchen-table-boat-building!) |

|

So now I see it comes quite close: this could happen when I start doing this scale 1:1 (side panels not matching in the build). |

|

And also I made two decks (real length: 75cm) which I planned (a) as decks and (b) when placing a bulkhead also as buoyancy compartments: approximated lift: 66liter/kg per deck/compartment. |

I noticed after installing these decks that there is much less torsion possible lengthwise in the canoe, so I guess adding to it’s longitudinal strength. This is of course “as expected” but I was surprised to “feel” it also in this simple carton board model.

So what did I learn:

- making a carton board model gave me insights into the building process using the plans and checking if I understood them: sort of “test-driving” the plans so to speak in just 2 hours effort;

- I saw (see the 2nd picture from above) where possible flaws/inaccuracies show up in the real build. So prepare and try to avoid the mistake in actual build;

- The model gave some insight into the structural strengths when adding e.g. the decks;

- For me it was fun to do (but I knew that: I always like to make models for fun even when I was a kid).

When the weather clears up here in The Netherlands (now still snowy!) I will start the actual 1:1 build and of course keep you all posted.

Update: The Wooden Model

Now I also made a wooden model of the cheap canoe. I based this on the carton board model. I only made the bottom and one side and glued them together using the duck-tape and glue method as you can see in the pictures. Instead of using epoxy glue however, I just glued the joint with polyurethanes (brand: “Bison” as readily available here in the Netherlands, here this is known as “construction glue”, especially intended for outside constructions). Disadvantage of this glue is that expands (with some force) and that the taping needs to be done really good or the joint will expand L. Upside of this glue (for me) is that it needs no mixing, is cheaper (I think) and does not have the toxic sensitivity issues associated with epoxy. Result is a joint that is indeed strong too. Not sure what I will use in the actual boat though. I the past I already glue two pieces of waterproof 4mm plywood together with this glue and had it submerged in a tin of water for 1 week: still a very strong glue composition: no difference with before the submergence.

|

Wooden model and carton model next to each other. I already removed most of the duck tape here. See the joint. I applied more glue in the middle part. |

|

Detail of the PU-glue joint. Quite strong! |

|

Trying to forcefully breaking the joint resulted in the 3mm side plywood to be breaking internally (unlayering), and the PU joint still in place! |

The plan is to make the actual boat in the summer holidays!

|